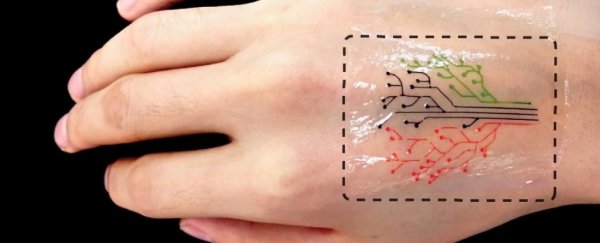

Researchers at MIT have invented a temporary "tattoo" made from genetically programmed living cells. Their prototype looks like a stick-on patch with a pattern in the shape of a tree.

It's divided into sections printed with a slurry containing live bacteria that fluoresce when they come into contact with particular compounds. When the skin under the patch has been exposed to these substances, the corresponding section of the tree lights up.

Research and development into stimuli-responsive materials that can be developed into smart materials has been going on for decades. A material that responds to heat, for instance, can be used to created self-assembling robots or moving robots; a material that responds to chemicals can be used as a chemical sensor.

And because 3D-printing is an accessible way to create custom objects at low cost, it's become a well-used method for creating experimental objects in laboratory settings - including stimuli-responsive materials.

But a team of engineers led by MIT professor Xuanhe Zhao realised that there may be a way to use living cells - easily obtained and easily programmable - in a 3D-printed reactive material.

Previous research into this area had already found that at least mammalian cells wouldn't work for this. They can't survive the harsh conditions of 3D-printing, such as the shear force during extrusion and the UV exposure during crosslinking, a common method of curing 3D-printed materials.

"It turns out those cells were dying during the printing process, because mammalian cells are basically lipid bilayer balloons," said co-author Hyunwoo Yuk. "They are too weak, and they easily rupture."

Bacterial cells with a protective cell wall, on the other hand, are much tougher. And, as it so happens, these cells are compatible with most hydrogels - materials made from water and polymer used for a variety of laboratory and medical applications.

Using bacterial cells that had been genetically programmed to fluoresce in response to various chemicals, the team developed an ink made of hydrogel, the cells, and a mix of nutrients to keep the cells alive.

The resulting ink is fine enough to be printed at a high resolution of 30 micrometres, or 0.03 millimetres. The team printed the test pattern onto elastomer, then stuck it to skin that had been smeared with chemicals.

Over the course of several hours, parts of the tree pattern lit up as the bacteria came into contact with its chemical stimuli.

They also engineered bacterial cells that could communicate with each other, fluorescing when they received a certain signal from another cell.

They tested this in a 3D structure, overlaying two thin sheets printed with hydrogel filaments. They only lit up where they came in contact with each other and received the communication signal.

"This is very future work, but we expect to be able to print living computational platforms that could be wearable," Yuk said.

In the shorter term, the team is looking to produce chemical sensors, and drug delivery systems that can be programmed to release drugs or glucose into the body over time.

The research was funded by the Office of Naval Research, National Science Foundation, National Institutes of Health, and MIT Institute for Soldier Nanotechnologies, and has been published in the journal Advanced Materials.