Researchers from the University of Wollongong in Australia have 4D printed a valve that automatically opens and contracts under the influence of water and temperature - and it's just one of the many applications of technology that promises to revolutionise how we build objects forever.

Already, 3D printing has opened up a whole world of research possibilities. We're now able to custom-print bionic body parts, print our own guns and even print entire buildings. But 4D printing adds a whole other dimension to this technology: time.

This means that researchers are now able to custom-design and print an object, but also give it the ability to change its shape, fold itself or even self-assemble under the influence of different factors, such as temperature, pressure, magnetic field or even vibrations.

"4D printing is in essence 3D printed structures that can change their shape over time," lead researcher Marc in het Panhuis, from the University of Wollongong's ARC Centre of Excellence for Electromaterials Science, told Nicky Phillips from the Sydney Morning Herald. "They're like transformers."

For example, 4D printing can be used to create furniture that assembles itself when you heat it with a hairdryer - no Allen Key required. Or from a more scientific point of view, it can help create sensitive and responsive parts for machinery, medical research and robotics.

Just picture medical implants that can change their shape inside the body, or buildings that adjust themselves when it's hot, in order to save on heating and cooling requirements.

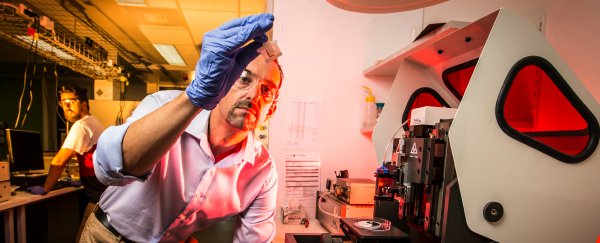

But this new development by the University of Wollongong is the first time researchers have been able to combine a 4D printer with four different types of hydrogel 'ink'. The process has been described in the journal Macromolecular Rapid Communications.

The valve itself was 3D printed using both tough and soft hydrogels, which are flexible but strong materials that can be embedded with different properties.

But what's really cool about this valve, is it's created a mechanic device that's completely autonomous - no power source or programming required.

"The cool thing about it is, is it's a working functioning device that you just pick up from the printer," in het Panhuis explained in a press release. "There's no other assembly required."

The actuators, or the parts that make the valve close, were printed in order to be activated solely by water.

"So it's an autonomous valve, there's no input necessary other than water; it closes itself when it detects hot water," said in het Panhuis.

The group is now also looking into more sophisticated designs, and are hoping to print pipes that can change size depending on water demands, as well as military objects that can self destruct when they're not longer required, as in het Panhuis told Phillips.

"When armies are on the battlefield they leave a lot of electronics behind. What if you could make 3D printed electronics that [once the soldiers leave] undergo transient behaviour once they become too hot, or too cold, or too wet so they completely disappear so the enemy can't use any of your materials," he said.

Given the way 3D printing has already changed our world, we're pretty excited about the possibilities that are going to come with adding an extra dimension.

Love science? Find out more about studying at the University of Wollongong.