Whether it's balancing on a blade of grass or taking on the appearance of frozen smoke, aerogels have been blowing us away with their amazing properties in recent years. And just when you thought they couldn't get any freakier, researchers have created a graphene aerogel that can support over 6,000 times its own weight.

Along with being super strong, the new aerographene is bendy, conductive, and mimics the structure of a plant stem. The unique properties of the material could make it an ideal component in flexible electronics such as smart windows, curved TV screens, and printable solar panels.

Speaking with ScienceAlert, Hao Bai, a materials engineer from Zhejiang University, says the graphene aerogel is unique from other aerogels available.

"Learning from nature always offers new insights for developing new materials and technology," says Bai. "Our graphene aerogel is different from current aerogels in both microstructures and properties."

Weighing a minuscule 0.16 milligrams per cubic centimetre, graphene aerogel is 7.5 times lighter than air and about 1000 times less dense than water. This stuff is so light that you can balance it on a fluffy dandelion head or on the stamen of a flower. Out of all the aerogels, graphene aerogel is the least dense and considered one of the lightest solid materials on Earth.

Apart from blowing our minds, aerogels are already proving useful for a wide variety of applications, from cleaning up oil spills to creating high-energy batteries. Researchers have even managed to convert sunlight into water vapour at room temperature using graphene aerogel, which makes it possible to turn wastewater into drinkable water.

But when it comes to moving machine parts, flexible sensors, and bendable energy storage devices, researchers have struggled to create aerogels that have both the strength and resilience required for these applications.

"Strength and resilience are usually mutually exclusive in regular aerogels," Bai explains. "There is a high demand for strong and resilient aerogels in many important fields, but it is very difficult to achieve both of these properties."

In recent years, we've seen several attempts to achieve these properties in graphene aerogels, including through the use of 3D printing and freeze-drying. The problem with these processes is that they only produce graphene aerogels with a random architectural structure, which doesn't provide robust strength and resilience.

Looking at the natural world, the secret to the strength and bendiness of porous materials like plant stems comes down to how the material is arranged at the nanoscale. Even if the material itself is weak and porous, the highly organised arrangement of the material makes it strong and flexible.

"Many natural materials have developed unprecedented properties by building complex multiscale architectures," Bai says. "We wondered whether we could mimic these features to create an aerogel that is both strong and resilient."

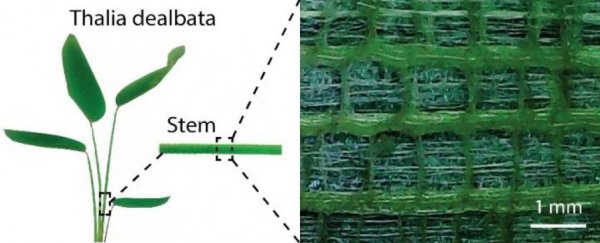

To find out, Bai and his team turned to the powdery alligator-flag (Thalia dealbata), a hardy aquatic plant native to South America and Mexico. Even though the stem of this plant is slender and porous, it can withstand frequent wild winds thanks to its grid-like layered microstructure.

Taking cues from the plant's complex structure, the team used bidirectional freezing to mimic its architecture in graphene aerogel.

First, graphene oxide particles are dispersed in water, which form sheets as the liquid freezes.

Once completely frozen, the graphene oxide sheets form a three-dimensional network similar to the structure of ice crystals.

Finally, thermal reduction and sublimation produced graphene aerogel that mirrored the bridged layers of the powdery alligator-flag stem.

Next, the team put the aerogel through a series of compression tests to see whether its architecture produced strength and resilience. After 1,000 compressive cycles the researchers discovered that the graphene aerogel was capable of supporting over 6,000 times its own weight and spring back to its original state. The material also retained 85 per cent of its strength before compression was applied.

This is a significant jump from aerogels with a random architecture, which tend to retain just 45 per cent of their original strength after only 10 compressive cycles.

Although the enormous strength and resilience of the aerogel is amazing all on its own, the researchers also wanted to know whether the material was conductive under compression.

The team placed the aerogel in a circuit with an LED, and applied different compression strains. Sure enough, they found that the aerogel remained conductive even when compressed, indicating that it could play a role in flexible electronics and sensors.

Now that the researchers have finally created a graphene aerogel that is strong, resilient and conductive, the next step is figuring out whether nature can be used as a reference for developing other kinds of aerogels, such as cellulose-based or polymer-silica composites.

"Learning from natural models will definitely help to develop new materials," Bao told ScienceAlert. "The challenges still remain in how much we can discover and understand nature's secrets, and if we can really mimic nature with synthetic approaches."

We can only dream of what nature will help us design next.

The research was published in ACS Nano.