Chemists in Belgium have come up with a new method that turns sawdust, old paper, straw, wood and any other non-edible plant waste into useful products that can be converted into gasoline and plastic.

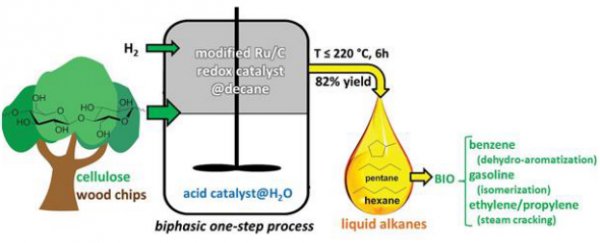

Using the new two-step chemical process (which is described in the illustration above), the scientists from research organisation KU Leuven have converted the cellulose in sawdust into hydrocarbon chains - a transition that takes around a day and a half. These chains can then be used to produce a chemical that requires one more step to be distilled into gasoline.

As we quickly run out of fossil fuels, scientists are urgently looking for more sustainable replacements. One option is biofuels, but these fuels currently use food crops, which are desperately needed to help feed the one in nine people around the world that are undernourished.

The new process creates a similar product, but it uses cellulose, a substance that's found in the non-edible parts of crops that would be waste anyway. This product can be easily added to regular gasoline to make a more sustainable fuel for cars already on the road.

The team created it by isolating the chains of five to six hydrocarbon atoms from cellulose.

"At the molecular level, cellulose contains strong carbon chains. We sought to conserve these chains, but drop the oxygen bonded to them, which is undesirable in high-grade gasoline," said one of the team members, Bert Sels, in the release.

"This is a new type of bio-refining, and we currently have a patent pending for it," added co-researcher Bert Lagrain in the release. "We have also built a chemical reactor in our lab: we feed sawdust collected from a sawmill into the reactor and add a catalyst – a substance that sets off and speeds the chemical reaction. With the right temperature and pressure, it takes about half a day to convert the cellulose in the wood shavings into saturated hydrocarbon chains, or alkanes."

And the applications go beyond fuel - they can also be used to produce more sustainable plastics. "The green hydrocarbon can also be used in the production of ethylene, propylene and benzene - the building blocks for plastic, rubber, insulation foam, nylon, coatings and so forth," said Sels.

The process opens up a range of possibilities for turning non-food plant waste into something both economically an environmentally useful.

"From an economic standpoint, cellulose has much potential," said Sels in the release. "Cellulose is available everywhere; it is essentially plant waste, meaning it does not compete with food crops."

The results are published in the journal Energy & Environmental Science.

We hope it's a breakthrough that hits the market soon, giving developers yet another option for more sustainable transport in the future. But while we're waiting, we will happily settle for sustainable jetpack travel, as displayed here by Veritasium.