Researchers have achieved a major turning point in the quest for efficient desalination by announcing the invention of a graphene-oxide membrane that sieves salt right out of seawater.

At this stage, the technique is still limited to the lab, but it's a demonstration of how we could one day quickly and easily turn one of our most abundant resources, seawater, into one of our most scarce - clean drinking water.

The team, led by Rahul Nair from the University of Manchester in the UK, has shown that the sieve can efficiently filter out salts, and now the next step is to test this against existing desalination membranes.

"Realisation of scalable membranes with uniform pore size down to atomic scale is a significant step forward and will open new possibilities for improving the efficiency of desalination technology," says Nair.

"This is the first clear-cut experiment in this regime. We also demonstrate that there are realistic possibilities to scale up the described approach and mass produce graphene-based membranes with required sieve sizes."

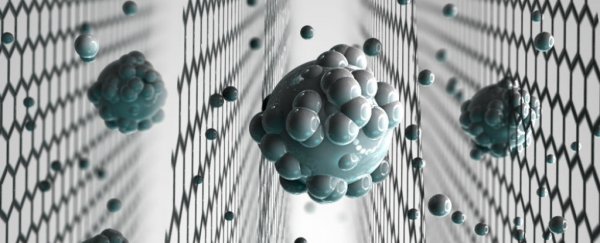

Graphene-oxide membranes have long been considered a promising candidate for filtration and desalination, but although many teams have developed membranes that could sieve large particles out of water, getting rid of salt requires even smaller sieves that scientists have struggled to create.

One big issue is that, when graphene-oxide membranes are immersed in water, they swell up, allowing salt particles to flow through the engorged pores.

The Manchester team overcame this by building walls of epoxy resin on either side of the graphene oxide membrane, stopping it from swelling up in water.

This allowed them to precisely control the pore size in the membrane, creating holes tiny enough to filter out all common salts from seawater.

The key to this is the fact that when common salts are dissolved in water, they form a 'shell' of water molecules around themselves.

"Water molecules can go through individually, but sodium chloride cannot. It always needs the help of the water molecules," Nair told Paul Rincon from the BBC.

"The size of the shell of water around the salt is larger than the channel size, so it cannot go through."

Not only did this leave seawater fresh to drink, it also made the water molecules flow way faster through the membrane barrier, which is perfect for use in desalination.

"When the capillary size is around one nanometre, which is very close to the size of the water molecule, those molecules form a nice interconnected arrangement like a train," Nair explained to Rincon.

"That makes the movement of water faster: if you push harder on one side, the molecules all move on the other side because of the hydrogen bonds between them. You can only get that situation if the channel size is very small."

There are already several major desalination plants around the world using polymer-based membranes to filter out salt, but the process is still largely inefficient and expensive, so finding a way to make it quicker, cheaper, and easier is a huge goal for researchers.

Thanks to climate change, seawater is something we're going to have plenty of in the future - Greenland's coastal ice caps which have already passed the point of no return are predicted to increase sea levels by around 3.8 cm (1.5 inches) by 2100, and if the entire Greenland Ice Sheet melts, future generations will be facing oceans up to 7.3 metres (24 feet) higher.

But at the same time, clean drinking water is still incredibly hard to come by in many parts of the world - the UN predicts that by 2025, 14 percent of the world's population will encounter water scarcity. And many of those countries won't be able to afford large-scale desalination plants.

The researchers are now hoping that the graphene-based sieve might be as effective as large plants on the small scale, so it's easier to roll out.

Graphene oxide is also a lot easier and cheaper to make in the lab than single-layers of graphene, which means the technology will be affordable and easy to produce.

"The selective separation of water molecules from ions by physical restriction of interlayer spacing opens the door to the synthesis of inexpensive membranes for desalination," Ram Devanathan from the Pacific Northwest National Laboratory, who wasn't involved in the research, wrote in an accompanying Nature News and Views article.

"The ultimate goal is to create a filtration device that will produce potable water from seawater or wastewater with minimal energy input."

He added that the next step will be to test how durable the membranes are when used over long periods of time, and how often they need to be replaced.

The research has been published in Nature Nanotechnology.