A new technique for making artificial molecules in the lab has been developed by researchers in Switzerland, and it opens up the possibility of new micro-robots and other microscopic structures being produced for a specific task - such as delivering medicine into targeted areas in the body - in a way that closely mimics the body's natural processes.

"So far, no scientist has succeeded in fully controlling the sequence of individual components when producing artificial molecules on the micro-scale," said lead researcher, Lucio Isa from ETH Zurich.

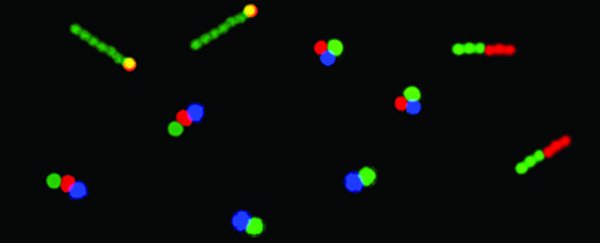

The process to create these artificial molecules starts with microspheres made of polymer or silica - 1 micrometre in diameter - which are placed side-by-side in tiny indentations and engraved in polymer templates. The indentations set the form of the finished object and heat is then used to bond the spheres together.

The team says this new procedure is more effective than other micro-3D printing technologies because it enables scientists to build single micro-structures from multiple materials. This means they can arrange artificial molecules in the sequence and with the geometry of their choosing.

It also enables them to precisely define magnetic, non-magnetic, and differently charged areas. Small rods, tiny triangles, and basic 3D objects can be created, though the research team wants to expand the capabilities of the process further.

The researchers say the practical benefits of the process could range from self-propelled micro-carriers that move in an external electric field and micro-mixers for lab-on-a-chip applications, to (eventually) micro-robots for biomedical applications which are able to grab, transport, and release other specific micro-objects.

They also think their new technique could be used to assemble larger 'superstructures' for use in areas such as photonics (light-based signal processing).

Thanks to the level of control the team has managed to develop, the process is extremely versatile. "In principle, our method can be adapted to any material, even metals," said Isa.

"The full programmability of our approach opens up new directions not only for assembling and studying complex materials with single-particle-level control but also for fabricating new microscale devices for sensing, patterning, and delivery applications," concludes the study, which has been published in the journal Science Advances.