Imagine, if you will, a microscopic submarine, motoring around inside your blood vessels, delivering medicine, or perhaps performing surgery all on its own.

This is the sort of future theoretical physicist Richard Feynman used to fantasise about, and yet today, we're still stuck on the swimming part.

For a vessel at such a tiny scale, the fluid in our blood vessels practically feels like molasses. Recreating a microswimmer with powers akin to those of sperm or bacteria – powerful enough to push through such a thick fluid – has proved quite the challenge.

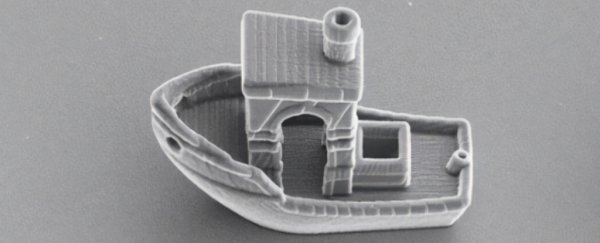

So far, scientists have built only the simplest of artificial microswimmers, mostly in the shape of rods and spheres. Now, we have reached new heights with microprinting technology, and Benchy the tugboat is the proof.

Why a tugboat? This publicly available 3D model is a commonly used benchmark designed to test and calibrate 3D printers, pushing them to their limits with a variety of shapes and angles.

Now, researchers from Leiden University in the Netherlands have shrunk Benchy down to 30 micrometres – which means if the width of a hair is a three-lane highway, this boat could ride the inside lane.

We may not have little boats riding through our bloodstream anytime soon, but that's beside the point. Achieving this complex structure demonstrates that two-photon polymerisation, the 3D microprinting technique used in the study, can be harnessed to produce truly complex shapes.

Starting with a sphere of photosensitive polymer, the team used this tech to devise increasingly complex microswimmers, some of which can be seen in the image below (the 'starship' in figure b looks quite familiar, too).

"A laser is focused inside a droplet that locally hardens in the focal spot of the laser," Daniela Kraft, senior author of the study, told Gizmodo.

"By moving the laser through the droplet in a controlled way, we can write the swimmer shape that we want."

A spiky sphere, a 'starship', a spiral, a helix, a trimer, and Benchy. (Doherty et al., Soft Matter, 2020)

A spiky sphere, a 'starship', a spiral, a helix, a trimer, and Benchy. (Doherty et al., Soft Matter, 2020)

Benchy itself has a ton of fine details, including several portholes and an open cabin that's particularly tricky for a 3D printer to replicate.

"Here, the true advantage of using a 3D microprinter can be seen," the authors note in their study.

"It becomes very simple to build complex details and anisotropy into the particles, such as spikey spheres, boats, spaceships, or more conventional shapes like trimers."

The team says their results open the door to studying how the motion of certain microswimmers and their interaction with the environment changes with their shape, allowing us to better understand the mechanisms behind propulsion in biological structures.

The potential of the tech is so immense that it could one day create microswimmers with a wide range of geometries in almost any desired shape.

"Ultimately," the team writes, "[the technology] will allow a greater control and design of the behaviour of synthetic microswimmers, useful for applications in therapeutic diagnostics and drug delivery."

The study was published in Soft Matter.