Scientists have developed a new type of artificial muscle fibre based on nylon, which could one day render our future robot companions more realistic than ever.

Unlike previous synthetic muscles, this technology is cheap and simple to produce, which makes it a better option if we want our droids to be able to flex, move, and repair themselves in much the same way as flesh-and-blood people.

Robot muscles based around nylon have been tried before, but researchers at MIT have developed a new technique to shape and heat the fibres, giving the artifical muscles greater scope to bend and contract.

To make the system work, ordinary nylon fishing line is compressed, so the cross-section takes on a rectangular or square shape rather than a circular one.

With the application of heat – via a combination of electric resistance heating, chemical reactions, and laser beams – the researchers were then able to get the wire to move from side-to-side, in a circular motion, and in a figure-8 shape.

The bending is caused by the natural tendency of highly oriented nylon (where the fibres run in the same direction) to shrink in length but expand in diameter when heat is applied.

The researchers found that if one side of the fibre is heated, it begins to contract faster than the heat can penetrate to the other side, which creates the bending motion.

Based on initial testing, these new nylon fibre muscles should be good for 17 bend-and-retract cycles per second, and at least 100,000 bending cycles in total – meaning your robot butler of the future should enjoy plenty of longevity.

"This is a simple idea that works really well," says engineer Geoffrey Spinks from the University of Wollongong in Australia, who wasn't involved in the research.

"The materials are inexpensive. The manufacturing method is simple and versatile. The method of actuation is by simple electrical input. The bending actuation performance is impressive in terms of bending angle, force generated, and speed."

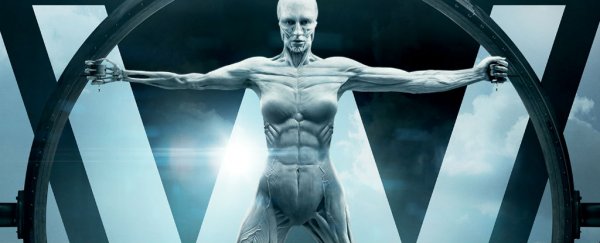

The uses for this type of technology go far beyond Westworld-style robots. A more naturally flexible muscle material like this could one day lead to numerous applications, including being fitted to biomedical devices.

"One can imagine many applications for this type of actuator in the medical and instrumentation fields," says bioengineer Andrew Taberner from the University of Auckland in New Zealand, who wasn't involved with the study. "I expect this work will become highly cited."

Other potential uses could be in vehicles' exterior panels, helping cars to adapt to more aerodynamic shapes, or in clothes, where the fibres could expand or contract to give us things like self-lacing shoes, or garments that exactly fit the shape of your body.

There's no word yet on when we'll see this technology in actual products, but we're hoping we don't have too long to wait.

The research has been published in Advanced Materials, and you can watch a video of the technology in action below: