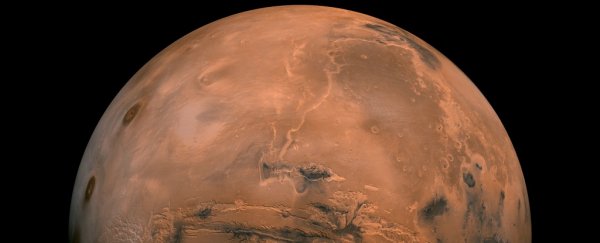

When humanity eventually decides to colonise another planet - looking at you, Mars - one of the first things researchers will need to figure out is how to build structures to keep our delicate bodies safe from harsh environmental conditions.

Since sending prefabricated structures or materials to Mars or the Moon is incredibly expensive - it costs roughly US$100,000 to get a single kilogram to the Moon alone - experts have been looking for ways to build directly on alien landscapes. Now, we might just have the answer: 3D printers that make building materials out of Martian and lunar dust.

Dubbed Selective Separation Sintering (SSS), the new process is able to take common materials found on Mars and the Moon and turn them into actual building materials like tiles and bricks. Basically, the process works by taking ceramics like magnesium oxide and regolith (soil) that are readily available on Mars and the Moon and then heating them to ultra-high temperatures to form objects.

"[Selective Separation Sintering] is a novel powder-based additive manufacturing method that can build parts of various scale out of polymers, metals, ceramics and composites," said Behrokh Khoshnevis, an engineer at the University of Southern California.

Khoshnevis developed the technique and recently entered it into NASA's In-Situ Materials Challenge, which pitted teams against each other to see if anyone could come up with a way to use common lunar and Martian materials in construction. Khoshnevis's process won this year's top prize.

Not only will Selective Separation Sintering allow us to take a single machine to Mars that's capable of churning out common building materials, it could also find use on the International Space Station.

Astronauts could use it to print tools and spare parts whenever needed, which is great, because it's a long trip to the hardware store when you're orbiting some 200 or so miles (321 km) above Earth.

"It could make space pioneering more cost-effective and feasible," says Khoshnevis. "There are no viable, direct, high-temperature metal, ceramic or composite fabrication methods that can work in zero-gravity conditions. SSS will be the first such process."

The next step for Khoshnevis and his award-winning idea is to test the process in a vacuum chamber to ensure that everything works under space-like conditions.

There's no word yet about what will happen if those tests prove successful, but it's safe to say that if/when we finally make it to Mars, or end up building a lunar colony, a technique similar to this will likely be on the (3D-printed) table.