It's called 'range anxiety', and it's often pointed to as one of the key reasons why consumer uptake of battery-powered electric vehicles still hasn't really taken off.

In a nutshell, range anxiety is the fear that an electric car's battery won't hold enough juice to get you where you need to be going – and today's ultra-slow charging speeds (up to an hour or potentially much longer) don't really help the problem.

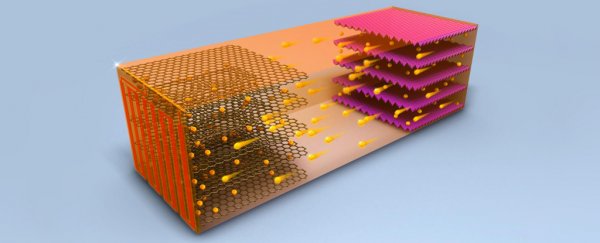

What might alleviate the issue though is a new kind of battery technology developed by scientists at Penn State University, which overcomes existing bottlenecks to offer an EV battery that takes only minutes to get back to 100 percent charge.

"We demonstrated that we can charge an electrical vehicle in 10 minutes for a 200 to 300 mile range," says chemical engineer Chao-Yang Wang.

"And we can do this maintaining 2,500 charging cycles, or the equivalent of half a million miles of travel."

That last part's important, because EV batteries – much like the ones in your smartphone or notebook – are lithium-ion batteries, which have a limited number of charge/discharge cycles before they degrade past the point of being useful.

One of the factors that can hasten that degradation is heat (which is why companies always tell you not to let the batteries in your personal electric devices get too hot, as it can shorten their overall lifespan).

That unfortunate reality is also an obstacle to something the US Department of Energy wants to achieve for EV batteries: a standard called extreme fast charging (XFC), which the body hopes will enable EV batteries that can be fully charged to a 200-mile range in less than 10 minutes.

According to the Penn team, their new battery design - if scaled - could meet this ambitious technological goal, thanks to a workaround that sidesteps one of the biggest challenges to achieving XFC.

"A critical barrier to XFC is Li plating, which usually occurs at high charge rates and drastically deteriorates battery life and safety," the researchers explain in their new paper.

Li plating happens when lithium deposits form around the anode of the battery during charging.

Even though high heat is bad for lithium-ion batteries, though, increasing temperatures for short periods seems to actually result in less Li plating, the team's research reveals.

"In the past, it was universally believed that lithium ion batteries should avoid operating at high temperatures due to the concern of accelerated side reactions," says Wang.

"This study suggests that the benefits of mitigated lithium plating at the elevated temperature with limited exposure time far outweigh the negative impact associated with exacerbated side reactions."

Specifically, the researchers found that batteries temporarily heated to be 60 degrees Celsius (140 degrees Fahrenheit) for the ~10 minutes during which they were charged, could achieve the theoretical XFC standard, while lasting some 1,700 charge cycles.

By contrast, a non-heated control battery in the experiment degraded after just 60 cycles. While heating a lithium-ion battery may seem unconventional (and definitely isn't something you should try at home), it delivered results here.

"Taking this battery to the extreme of 60 degrees Celsius is forbidden in the battery arena," says Wang.

"It is too high and considered a danger to the materials and would shorten battery life drastically."

In their controlled tests, though, the heating technique eliminated Li plating, but was short enough in duration to avoid the development of other harmful formations in the battery called solid-electrolyte-interphase (SEI) growths.

But the team isn't done yet. Now that they've effectively achieved the XFC goal – or at least the battery component of it – they're looking at what kinds of materials they might need to fully charge an EV battery in just 5 minutes.

So long, range anxiety. We hardly knew you.

The findings are reported in Joule.