In remote parts of the world, getting vital medication to the people who need them can be a real challenge, so researchers in the US have developed a tiny, portable bioreactor that can generate a variety of drugs from any location.

When a mixture of acids and cell extracts are fed into the reactor, it can produce proteins needed to treat everything from diabetes to anaemia, and various kinds of infections, and more efficiently than commercial devices in use today. "We show that the microscale bioreactor design produces higher protein yields than conventional tube-based batch formats and that product yields can be dramatically improved by facilitating small molecule exchange with the dual-channel bioreactor," the team from Oak Ridge National Laboratory reports.

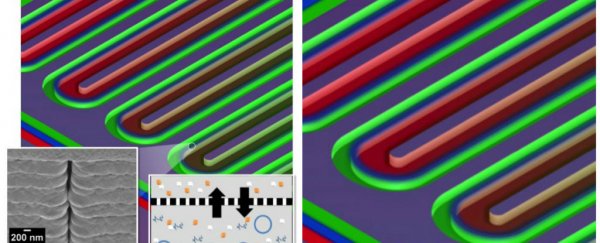

At the heart of the miniature bioreactor are two tightly wound, 4.9-metre-long (16 feet) channels that have been etched into a microscopic, porous silicon membrane. The reaction takes place in one channel, then the proteins pass through a special membrane into the other channel, ready for collection.

The exchange of metabolites, energy, and species that would otherwise inhibit protein production can be controlled through the membrane and the serpentine channels enclosing it.

Although there's still plenty of work to be done to make the device a commercial reality, it could one day provide vital treatments for those living or working in the middle of nowhere. The team hasn't yet made a full assessment of the costs of such a bioreactor, but it's believed that it would be less expensive than existing solutions.

One key difference with the new process is that the organic materials don't have to be kept alive in order to produce the necessary proteins - that makes long-distance transportation and long-term storage easier. Soldiers camped out far from civilisation, for example, could make use of the technology to treat various health issues (the US military agency DARPA provided some funding for the research).

Ultimately, the same device might be able to produce drugs that are in short supply or prohibitively expensive. Another potential use for the bioreactor is in disaster zones where established medical channels and infrastructure have broken down.

"With this approach, we can produce more protein faster, making our technology ideal for point-of-care use," said lead researcher, Scott Retterer. "The fact it's cell-free reduces the infrastructure needed to produce the protein and opens the possibility of creating proteins when and where you need them, bypassing the challenge of keeping the proteins cold during shipment and storage."

The findings have been published in the journal Small.