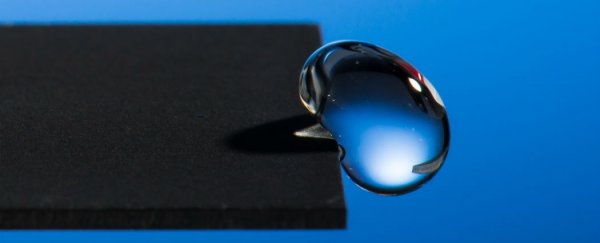

Researchers in the US have invented a self-cleaning metal that is so super-hydrophobic, water droplets will just keep bouncing off it until they roll away.

Inspired by natural materials such as the water-repellent lotus leaf, super-hydrophobic materials have been popping up all over the place of late. We've seen a new, super-durable, super-hydrophobic coating for use in power plants announced in 2013, a spray-on coating for boots and airplanes announced in mid-2014, and just a few months ago, researchers in China invented a super-hydrophobic coating that's so good, it can even be used on sex toys. A couple of weeks ago, I got the opportunity to test-run a new Australian-made super-hydrophobic t-shirt, and watched as little droplets of tomato and soy sauce rolled all over its pristine white surface.

But as cool as each of these inventions are, the effect will eventually wear off on each and every one of them, because the materials are coated in a super-hydrophobic substance - they aren't super-hydrophobic themselves. And that's why this new metal is so exciting. It has its super-hydrophobic properties built right into it, which means it will remain effective forever.

"We're able to change the surface structure of almost any piece of metal so that we can control how liquid responds to it," said one of the team, Chunlei Guo, associate professor of optics at the University of Rochester, in a press release. "We can even control the direction in which the liquid flows, or whether liquid flows at all."

To create the self-cleaning material, Guo's team blasted the surface of an alloy made from platinum, brass and titanium using an ultra-fast burst of laser light. And when we say "ultra-fast", we mean it - each burst is a mere femtosecond long, which equates to just a few quadrillionths of a second. Or, as the team describes, "a femtosecond is to a second what a second is to about 32 million years… [and] unleashes as much power as the entire electric grid of North America does, all focused onto a spot the size of a needlepoint".

These bursts alter the structure of the metal on a nanoscale, creating minuscule pits, globules and strands all over the surface. These nanostructures determine how much or how little liquid molecules are attracted to the surface molecules of the metal, and the effect can be turned up or down depending on the setting of the laser. This means that on one setting, the metal can be rendered super-hydrophilic, which means it bonds incredibly well with liquids, causing them to spread rapidly across the surface like a big hug. On another setting, it will become super-hydrophobic, causing the liquid to bounce right on out of there.

"Imagine a huge waterway system shrunk down onto a tiny chip, like the electronic circuit printed on a microprocessor, so we can perform chemical or biological work with a tiny bit of liquid," says Guo. "Blood could precisely travel along a certain path to a sensor for disease diagnostics. With such a tiny system, a nurse wouldn't need to draw a whole tube of blood for a test. A scratch on the skin might contain more than enough cells for a micro-analysis."

Plus, their metal is black, which means it will be extra useful for applications where light collection is required, such as sensors and solar panels, they report in the journal Applied Physics Letters. Their material is self-cleaning, anti-corrosion, anti-icing, and anti-microbial. Imagine air conditioners and fridges that never accumulate ice, shelves that never need dusting, and surfaces that harmful microbes can never take up residence on.

The invention has even caught the attention of the Bill and Melinda Gates Foundation, because of its potential to facilitate the easy collection of rain water in developing countries around the world. "In these regions, collecting rain water is vital and using super-hydrophobic materials could increase the efficiency without the need to use large funnels with high-pitched angles to prevent water from sticking to the surface," Guo said in the press release. "A second application could be creating latrines that are cleaner and healthier to use."

But, as Alexandra Ossola says at Motherboard, "it's nowhere near ready to be deployed in those real world scenarios where it's most needed". Right now, it takes one hour to laser-pattern a 2.5 cm by 2.5 cm sample of metal, which is just not feasible when you want to be creating huge funnels and toilets with the stuff. But it's still super-fun to watch it work, even if we have to wait a while to see it muscle its way into our lives.