Driving around on the Moon is not, one could say, the safest possible ride.

It's not the bumpiness that's so much an issue. It's the powder-fine dust. Agitated into the low-gravity environment, the tiny, charged particles hang in space and pose a major hazard to the intricate working of Earth's machinery.

Should humans one day live on the lunar surface for any extended period, we just might be able to turn that dirt – or regolith – into smooth, clean roads, new research has found. All you need is whopping a big lens.

"With the aim of consolidating large structures from lunar regolith, the European Space Agency (ESA) project 'PAVER' – paving the road for large area sintering of regolith – studied whether the melting of regolith with a large beam of focused light is a suitable technology for paving applications on the Moon," writes a team led by engineer Juan‑Carlos Ginés‑Palomares of Aalen University in Germany.

Sintering is the process of creating a solid mass from small particles using pressure or heat without liquifying the material.

"The results of this study proved the viability of this technique for manufacturing large samples with interlocking capabilities in-situ that can be fabricated directly on the lunar surface and arranged for paving applications."

When it comes to planning a base of human operations on the Moon, the fewer items we need to ferry from Earth the better.

That's easier said than done. There's kind of not a lot up there, after all. There are rocks and dust; the surface layer of which is known as the lunar regolith. There's probably some ice. And there's a whole lotta sunshine; a lunar day-night cycle lasts 28 days.

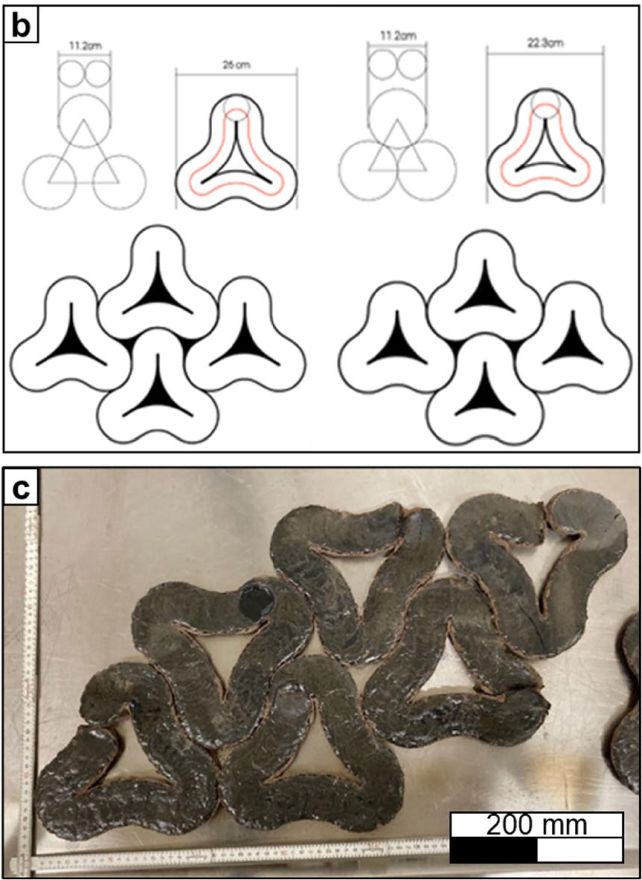

Ginés‑Palomares and his team wanted to establish if materials available on the Moon could be used to create materials from which roads might be built. A lens, they posited, could be used to focus sunlight in such a way that it creates a beam hot enough to melt the lunar dust, creating interlocking tiles with which a road can be paved.

Their experiments were conducted using a fine, gray, powdery dust known as EAC-1A. This is a simulant of the lunar regolith developed by the ESA, a mix of minerals in the same proportions on which they are found on the Moon.

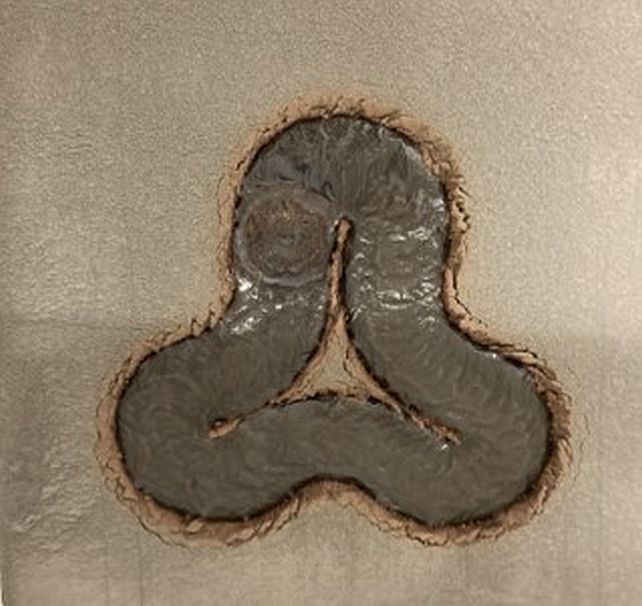

They also used a CO2 laser – a type of laser in which an electric current is discharged through carbon dioxide to produce a beam of light with a 45 millimeter (1.8-inch) diameter. They focused this beam of light on the EAC-1A, and traced patterns in the dust to melt specific shapes that could fit next to each other in an interlocking pattern. They tried different laser strengths to find the optimum heat to produce tiles.

And it worked. The researchers found a laser strength consistent with what could be achieved with sunlight on the Moon. The resulting tiles, they say, could be made on the Moon using lunar dust and a Fresnel lens with an area of 2.37 square meters (25.5 square feet) to focus the sunlight available up there – a pretty small piece of equipment, all things considered.

The researchers also tested the strength of their tiles, bearing in mind that lunar equipment is likely to be heavy. They found that the sintered material had a strength comparable to concrete.

With this, lunar explorers could potentially create tiles around 250 millimeters (9.8 inches) across to create paved roads and landing pads, and thus reduce the amount of harmful dust above the lunar surface, threatening to abrade equipment and clog delicate machinery.

The next step is to work on the robustness of the material. Although it was strong, it was prone to breaking, which could have something to do with microscopic defects they found using microscopy and scanning. Minimization of these defects would make for a much sturdier lunar road.

The research has been published in Scientific Reports.